Take a step to industry 4.0 with Luxmet's solutions

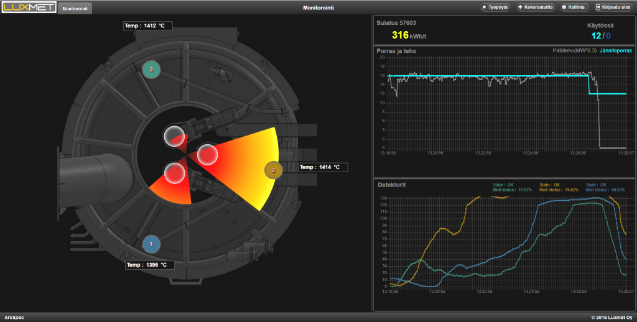

Electric Arc Furnace (EAF) process control

ArcSpec measures, shows, and analyzes the melting progression of the EAF hot spots and enables the optimal control of electrode power levels and other process variables.

Online temperature measurement

TempSpec is a real-time continuous temperature measurement system for challenging high-temperature metallurgical processes. Gain more control over your process.

Ladle furnace (LF) measurement solution

The temperature and composition of the molten slag in an LF directly affect the quality of the final product. ArcSpecLF, allows you to monitor and control both in real-time, using OES.

Interested to learn more about the different measuring methods for the Electric Arc Furnace?

We created a guide based on years of research to clarify what are the different methods for measuring the Electric Arc Furnace process and what are they good for.

News and articles

Real-Time Insight in the Ladle Furnace: The Fastest Way to Cut Costs and Improve Safety

In secondary steelmaking, the ladle furnace is where steel quality and production costs are decided. Final adjustments to slag and temperature determine whether a heat...

Succesfull Testing of Real-Time Slag Analysis at SSAB Ladle Furnace –Measurement Campaign by Luxmet

Picture: The temperature and composition of the molten metal in a ladle furnace directly affect the quality of the final product. Luxmet’s ArcSpecLF monitors both in...

Managing Slag in Ladle Furnaces: Top 3 Challenges and Solutions

Control bath basicity, slag composition, and desulfurization in ladle furnaces to improve steel quality, process efficiency, and extend equipment life.